Ultrasonic cleaning plants

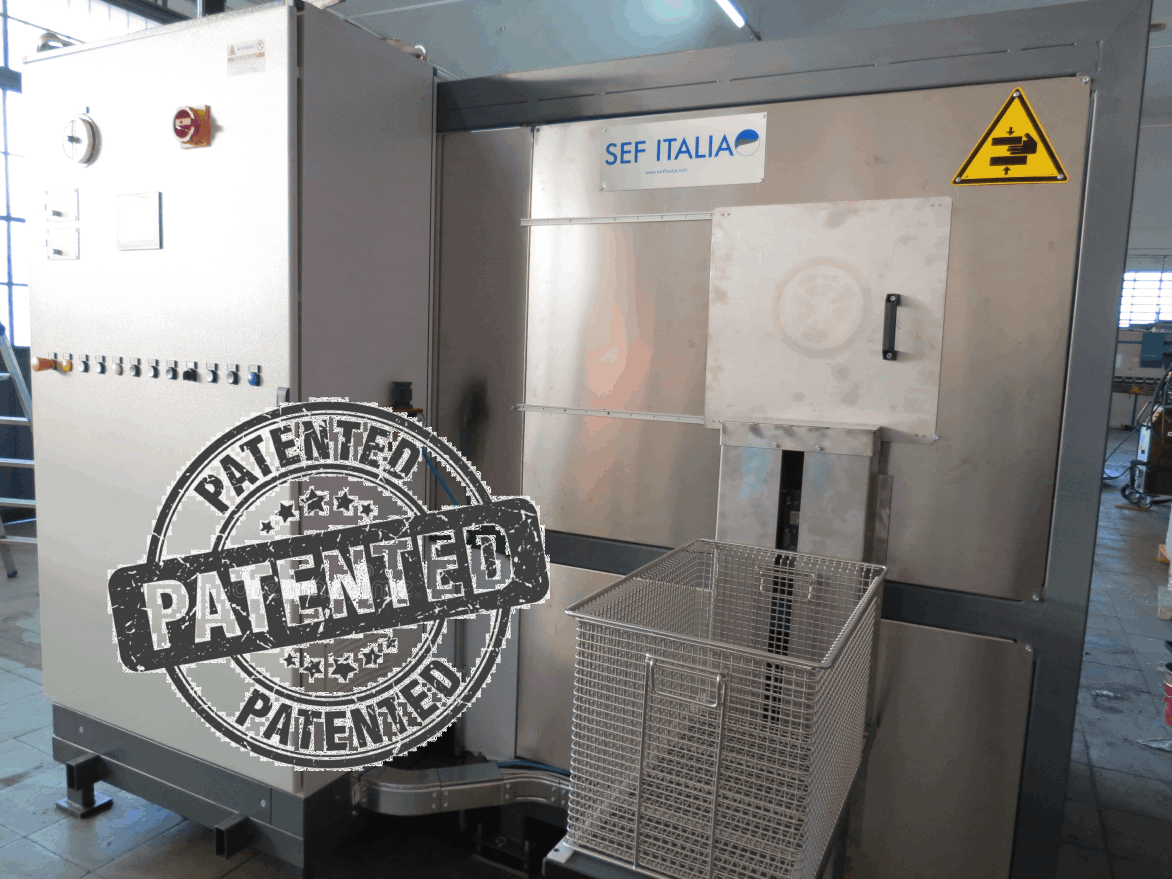

LM25 - Compact single-stage cleaning machine

LM25 is a patented compact single-stage cleaning machine for the cleaning and degreasing small metal parts and plastic materials.

Features:

low environmental impact system, solvents free;

high productivity: 1 load (about 25 lt capacity) every 10-15 minutes (including preparation, loading and unloading) with only 0.5% of detergent is equipped with ultrasound degreasing technology;

heating phase with saturated steam and subsequently vacuum drying;

small footprint space

LM25 has been designed for ultrasonic degreasing of small metal parts and plastic materials. The load capability is 450x300x h200 mm, about 25 liters).

During the cleaning cycle the load can be rotated, at the end of the cleaning cycle the machine automatically dries the pieces with a vacuum process.

The machine is working with water-based detergents, does not require rinsing and easily separates oils and greases from the pieces.

There is therefore no need for water purification but only the transfer for the purification of the exhausted product at the end of the cycle.

In our R & D department we always a ultrasonic system ready for carry out a test on your products, do not hesitate to contact our sales department to arrange a meeting.

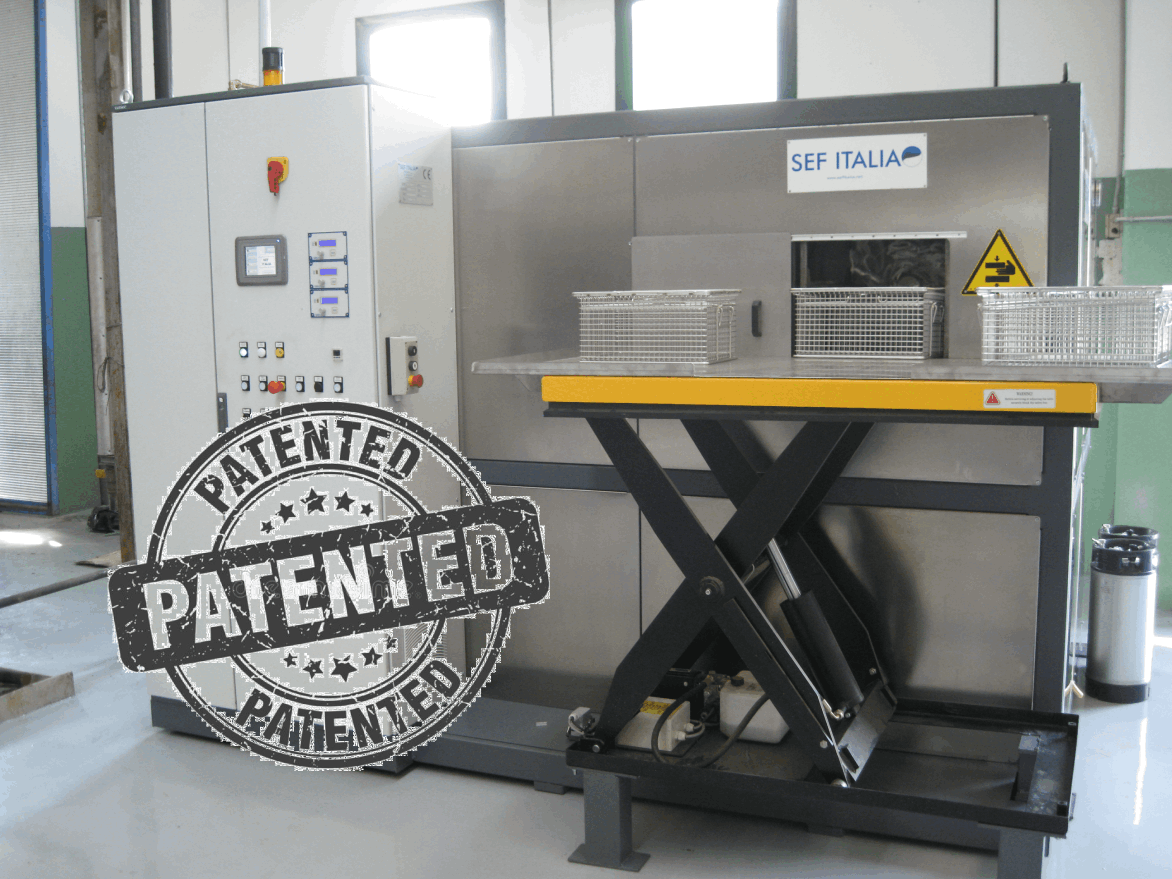

LM80 - Compact single-stage cleaning machine

LM80 is a patented compact single-stage cleaning machine, designed for the cleaning and degreasing small metal parts and plastic materials. The machine has been developed on the base of the LM25, but with more load capability.

Features:

low environmental impact system, solvents free;

high productivity: 1 load (about 80 lt capacity) every 10-15 minutes (including preparation, loading and unloading) with only 0.5% of detergent is equipped with ultrasound degreasing technology;

heating phase with saturated steam and subsequently vacuum drying;

small footprint space

LM80 has been designed for ultrasonic degreasing of small metal parts and plastic materials. The load capability is 600x400x h400 mm, about 80 liters).

During the cleaning cycle the load can be rotated, at the end of the cleaning cycle the machine automatically dries the pieces with a vacuum process.

The machine is working with water-based detergents, does not require rinsing and easily separates oils and greases from the pieces.

There is therefore no need for water purification but only the transfer for the purification of the exhausted product at the end of the cycle.

In our R & D department we always a ultrasonic system ready for carry out a test on your products, do not hesitate to contact our sales department to arrange a meeting.

Single-stage washing machines with four loading baskets

To increase the production capacity of our single-stage cleaning machine.

With this simple but innovative solution, it is possible to load 4 baskets instead of one, keeping the same performance on the cleaning process.

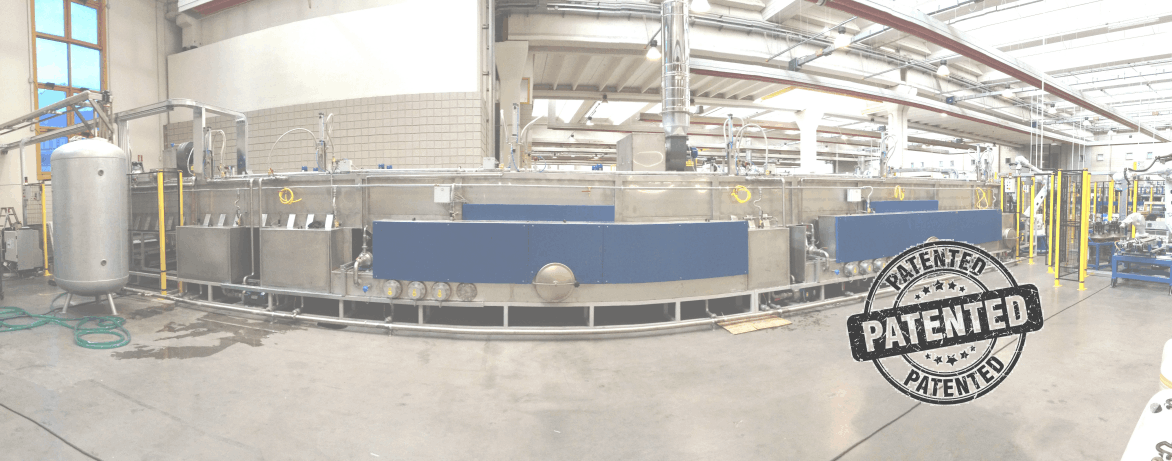

CLEANING PLANT FOR VARIOUS KIND OF HEAT EXCHANGERS

The largest European plant for washing heat exchangers used for boilers.

The plant is working with ultrasonic cleaning system using water-based, solvent-free detergents.

This system is capable of washing 1 pallet, consisting of 300 heat exchangers, in just 30 min.

The plant is equipped with two independent loading chambers, therefore the capacity is 4 pallets per hour, for a total of 1,200 batteries per hour.

If we consider that the standard systems in line were able to wash a maximum of 360 batteries per hour ...!

Furthermore, the cycle does not require the rinsing phase, this leads to an electrical and water saving, an increasingly precious asset, and to eliminating the water purification systems: using an evaporator, we can recovery the water and use it again on the cleaning cycle.

PDF | Published article

SPEEDY 4

SPEEDY 4 è un impianto riservato alle imprese con produttività elevate e alti standard qualitativi.

Innovativo ed affidabile è dotato di una macchina imbustatrice BG-80 e di un forno di sublimazione FC4 plus. E' un'evoluzione del forno standard utilizzato negli impianti Speedy, La sua peculiarità è quella di essere più largo (3 metri), in questo modo diventa possibile decorare nello stesso ciclo profili di dimensioni diverse, anche con taglio termico, senza differenze nella finitura.

E' possibile adattare il forno per renderlo adatto alla decorazione di profili molto pesanti (fino a 20 kg di peso/profilo).

La macchina imbustatrice, inoltre, scarica i profili direttamente sopra la zona di carico del forno agevolando l'operatore che si limita ad agganciare il profilo imbustato alle prese di depressione del forno.

I punti di forza di questo impianto sono la continuità di lavoro e la riduzione del personale addetto, traducibili nell' ottimizzazione dei costi di gestione.

Produttività: fino a 180 profili/ora

DOUBLE SPEED

DOUBLE SPEED deriva dalla serie di forni SPEEDY, con il fine di incrementare la produttività, seppur elevata, dell'impianto SPEEDY3.

Nasce da un'idea semplice ma rivoluzionaria: una sola imbustatrice alimenta due forni identici FC4/1. Ciò permette che la capacità produttiva di un normale forno SPEEDY3 raddoppi, utilizzando soltanto il 50% di personale in più.

Produttività: fino a 240 profili/ora

PDF | Layout

DOUBLE SPEED S

IL PIU' GRANDE E PRODUTTIVO IMPIANTO DI SUBLIMAZIONE DEL MONDO!

Questo straordinario impianto si evolve a partire dalla collaudata qualità del nostro impianto Double Speed.

E' un impianto completamente automatizzato, gli unici operatori necessari sono quelli nella zona di carico del forno, incaricati di assistere il corretto tensionamento del film sul profilo, e uno al carico dell'imbustatrice.

Produttività: 220-240 profili/ora con 9 operatori

L'impianto è dotato di un dispositivo che toglie automaticamente il film esausto all'uscita dei forni di sublimazione e lo invia ad un pallettizzatore.

In seguito, un carroponte automatico, preleva i profili decorati e li invia al magazzino automatico.

Grazie all'alta tecnologia utilizzata per automatizzare il processo di sublimazione, l'utilizzatore di questo impianto può beneficiare di un notevole abbattimento del costo di produzione.